Thursday, 9 December 2021 Case Studies

Techo Process Engineering Solutions & EastPack New Zealand

A Perfect Packhouse Storage Solution

Who: Techo Process Engineering Solutions & EastPack New Zealand

Where: EastPack Cool Store, Opotiki

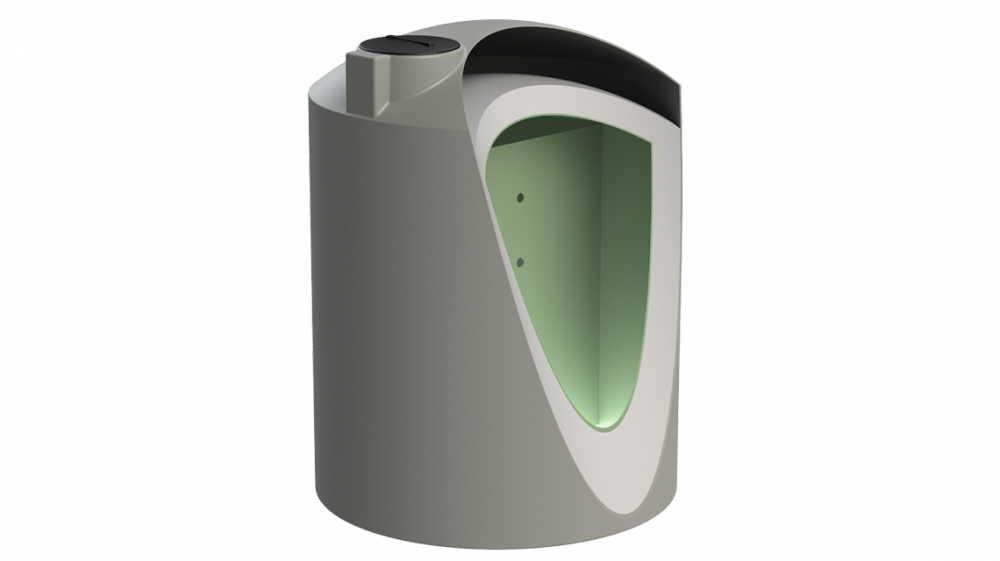

Products: 6000L R4 Insulated Tank with welded fittings plus seismic restraining kits with the mandatory PS1 that only Promax can supply.

Why: Techo Process Engineering Solutions was asked to convert a cool store at EastPack’s Opotiki kiwifruit packhouse. The existing freon cooling system was to be upgraded to an ammonia package chilling plant with glycol water tank, primary pump and three secondary loops supplying banks of evaporators. Techo asked Promax to supply the glycol water tank, but they needed more than a standard tank. They needed insulation, seismic restraints, and a very prompt delivery to meet the tightest of deadlines.

What: Promax supplied a 6000 litre R4 insulated tank. Glycol is a water-miscible coolant that requires a specialised insulated tank; the higher the R-Value the better the thermal resistance and therefore we provided an R4 insulated tank as opposed to a standard R0.5 tank. As well as this, we supplied a myriad of welded fittings. Plus, site specifications called for Promax seismic restraining kits with the mandatory PS1, something that only we can supply. What added to the complexity of this project was the tight timeline. The order was issued about three weeks before kiwifruit was to be stored at the packhouse! Promax relishes a challenge, and we were proud to deliver a specialised tank at short notice so that EastPack could continue to provide world-class kiwifruit in peak condition.