Thursday, 21 April 2022 Case Studies

Industrial Proliq Storage

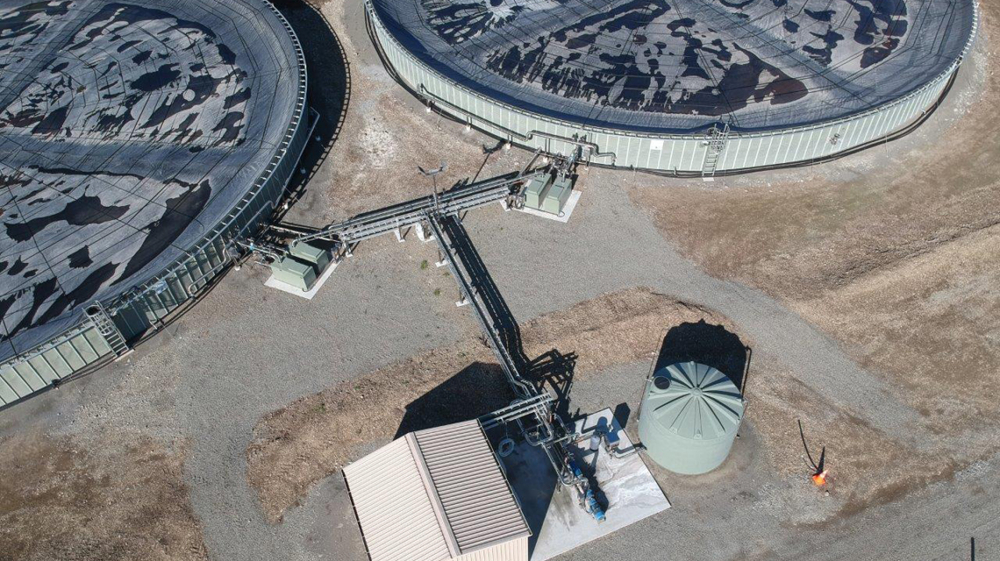

A Turn-Key Solution In The Dairy Industry

Who: Techo Process Engineering Solutions

Products: 1x 30,000L Industrial Tank and custom welded connections.

Where: South Canterbury

Why: Increased production from a new dairy factory in South Canterbury saw the need for additional Proliq storage. Proliq is the by-product left once lactose is removed from whey, and it is rich in protein, energy and minerals. Thanks to its high lactose level, Proliq is ideal as a low-cost animal feed supplement that nourishes livestock when energy levels are low. As a result, farmers can boost milk and beef production.

Techo, a company specialising in turn-key process engineering projects, was asked to manufacture a vast Proliq storage system at the new dairy factory. This included design, procurement, project management, commissioning, operator training and handover. Techo and Promax have previously worked together to great effect, so it was no surprise when we reunited on this Proliq storage project. Techo required a leak-proof tank as a vital component of the overall project, and they asked us to provide the strength and durability they required.

What: Promax supplied a 30 000 litre Industrial Tank and custom welded connections. Our heavy-duty industrial tanks are manufactured with increased wall thickness and strength to handle specific project applications and provide the safest and most efficient industrial liquid storage in New Zealand.

For this project, we fitted out the tank with welded spigots, backing rings and expansion joints to offer an intrinsically strong solution that benefits from flexible couplings to safeguard against leakage and stress over time.

To keep the project on track, we needed to deliver on time and within budget, as agreed. We kept our promise by supplying a customised tank on schedule and at the agreed price. It’s yet another example of Promax being a perfect project partner. We’ll never let the team down.

This case study was first published in May 2020.